Prototype Machining and Production Machining Services in Colorado

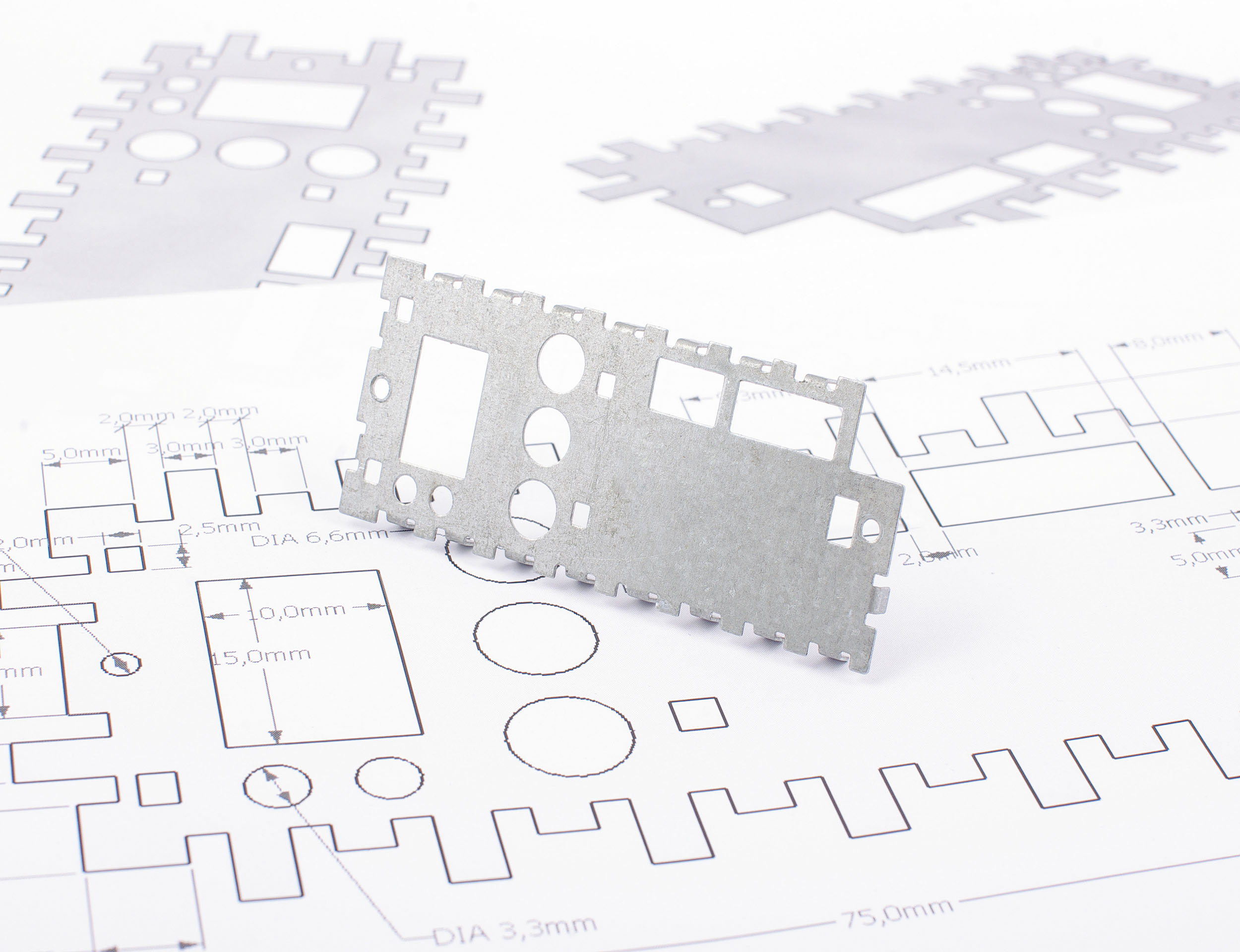

Machine shops, such as SCJ Machine, utilize CNC machining operations to prototype parts. CNC machining is preferable for parts that need to function as the final component when strength, mechanical stability, and precision are required. A machine shop well-versed in prototype machining is a perfect fit for final production runs due to their familiarity with the component design and specifics of the individual part, ultimately leading to a better end-use product.

Benefits of CNC Prototyping Services

The biggest advantage to CNC machine shop prototyping is the ability to clarify issues prior to production. A prototype provides a tangible object, revealing certain complexities that are often unable to be determined from a drawing. In turn, this can reduce or eliminate future production issues and expensive and time-consuming program modifications during production, keeping precision machining costs to a minimum. Other advantages include:

- Speed of production

- Part quality

- Material options

- Similarity to final product

Machine Shop Experienced in Prototype Machining and Low Volume Fixturing

For more than 25 years, SCJ Machine has created prototypes for the aerospace industry to customers’ exact specifications. As a prototype machine shop with a proven history of precision machining, we understand this stage of production is critical. We are proud to offer a full set of prototyping services along with the many benefits of working with a small machine shop. These include strong customer relationships, lower overhead, and greater attention to detail. Beyond that, SCJ also offers:

- Low and high volume production runs

- Fast turnaround

- Experience

- Flexibility

Fixturing and Prototyping Services in Denver, CO

SCJ Machine is an experienced CNC machine shop that offers fixturing, prototyping, and production in Colorado. SCJ offers customers a range of production CNC machining services, and is experienced in handling both high and low volume production for a variety of industries including aerospace, medical, firearm, agriculture, automotive, and defense spaces.

For prototypes and production parts, SCJ Machine offers all of the benefits of working with a small CNC machine shop: lower costs, quicker turnaround, and flexibility with a level of expertise and experience that is unmatched.