A History Rooted in Parts for the Aerospace Industry & Beyond

Rooted in a long-running interest in machining, SCJ Machine is where enthusiasm and expertise meet. Founder Zach Muszynski studied the trade for 27 years before finally opening his own shop in 2018. Throughout his career, Muszynski has specialized in the aerospace industry, producing parts for Ball Aerospace, Space X, and United Launch Alliance. But the capabilities of SCJ Machine extend far beyond a singular industry. From the medical field to the automotive parts and everything in between, we have the insight and technology to craft virtually any component that’s on your mind.

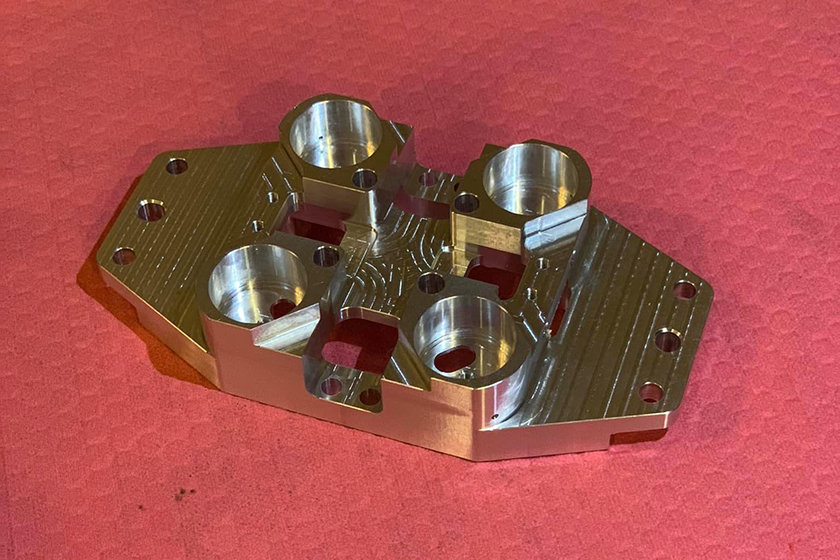

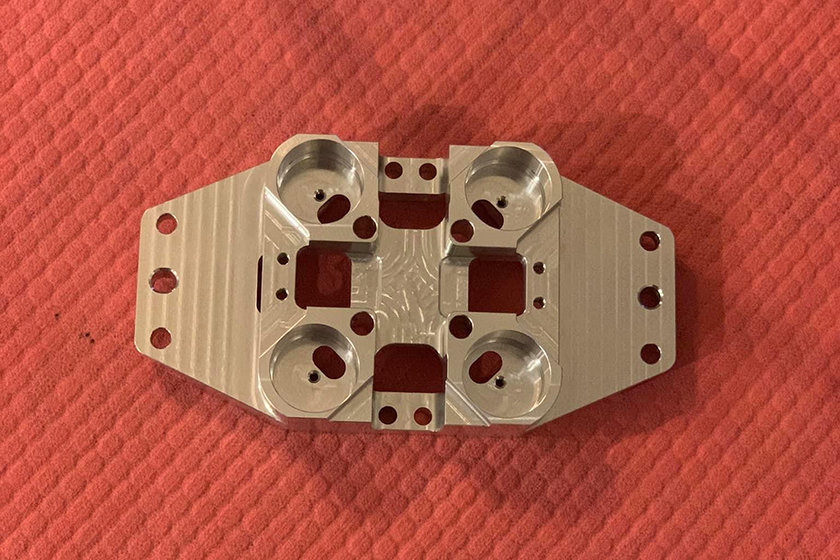

Quality Precision Parts

From design to prototype and everything in between, SCJ Machine is your one-stop-shop for CNC milling and machining. We utilize Mastercam 2018 to complement our extensive history of designing fixtures and programming complex parts. When it comes to material, we are capable of running most ferrous and non-ferrous metals alongside a wide range of plastic. For more information, visit our Services page.

Production Machining

For over 25 years, SCJ Machine has excelled at handling both high-volume and low-volume production machining projects. We are constantly keeping an eye out for new machining techniques to add to our repertoire. By doing so, we aim to produce parts faster and cheaper for large-volume orders.

Prototype Machining

We have specialized in producing prototypes for the aerospace industry for over 20 years, but are capable of creating them for a wide variety of industries and applications. We facilitate fixture design for production work and specialize in providing fast turnaround. SCJ Machine is capable of creating up to 50 prototype pieces for any given project.

CAD/CAM Programming

SCJ utilizes CAD/CAM programming for the fixture design and part programming processes. CAD programming allows us to create higher quality product designs at more efficient rate than our competitors. CAD/CAM programming is widely used by professionals within the machining industry due to its high accuracy and versatility, with designs and solids able to be imported.

Contact Us for a Quote Today »